Lithium Battery Thermal Runaway: Carbonate analysis from fire effluent with atmosFIR FTIR

Protea has developed a specialised application for its atmosFIR FTIR gas analyser to identify and quantify organic carbonate vapours generated during the thermal runaway of lithium-ion batteries. These carbonates — common as electrolyte solvents — include dimethyl carbonate (DMC), diethyl carbonate (DEC), ethyl methyl carbonate (EMC), propylene carbonate (PC), ethylene carbonate (EC, and vinylene carbonate( VC).

This application supports real-time monitoring during battery fire testing and safety certification, offering insights into thermal decomposition behavior, fire suppression validation, and hazard assessment.

Carbonate Chemistry in Battery Fires

Lithium-ion batteries use carbonate-based solvents in their electrolytes. Under thermal stress, these solvents vaporise and decompose, releasing carbonates and breakdown products such as:

- DMC, EMC, DEC, PC, EC, VC – Solvent vapours

- CO, CO2, HCl, HF, VOCs – Secondary gases

Measuring these vapours is critical for:

- Understanding the timing and mechanism of runaway

- Validating fire suppression systems

- Supporting battery pack fire modelling

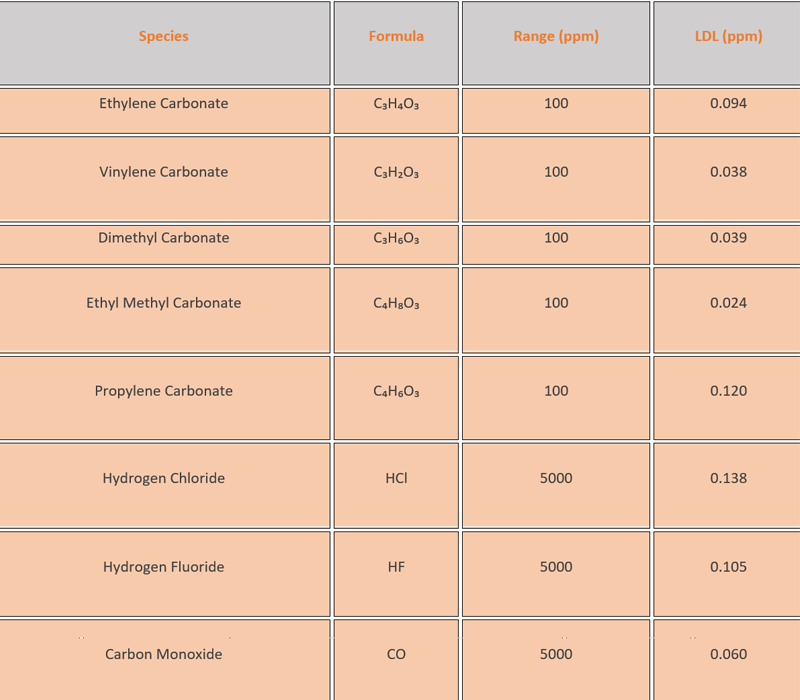

Detection and Quantification of Carbonates

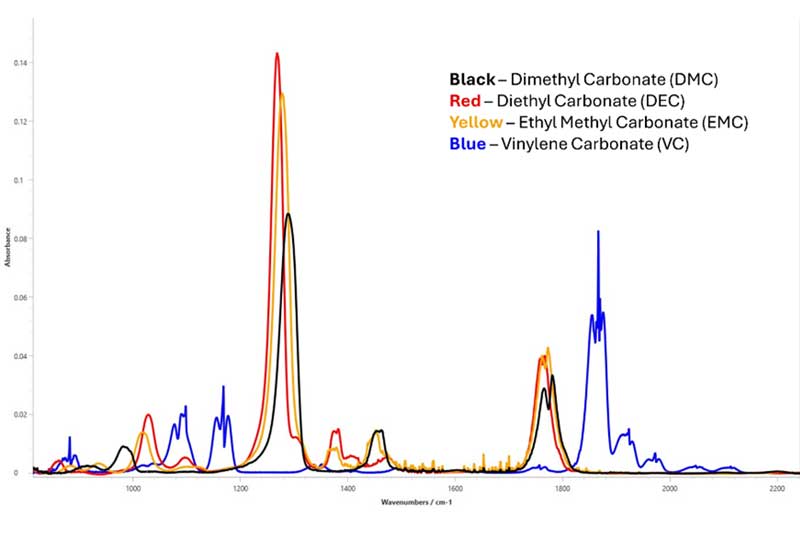

The atmosFIR analyser uses full-spectrum mid-IR spectroscopy to identify unique vibrational signatures of carbonate species. These compounds exhibit C–O–C stretches (~1050–1150 cm-1;) and C=O stretches (~1750–1850 cm-1), enabling robust speciation and quantification through Protea’s PLS-based chemometric modelling.

Protea's models are trained to detect subtle differences between carbonate species and to correct for interferences from background gases such as CO2, H2O, and CH4. This enables accurate speciated concentration outputs or total carbonates in real-time.

PAS Pro Software supports multiple calibration ranges, allowing the same hardware to achieve sub-ppm detection limits while also measuring concentrations up to thousands of ppm.

Sampling System

The atmosFIR system is configured with a robust sampling system designed for demanding fire effluent applications. Gases are extracted directly from the smoke density chamber via a heated sample line and heated filter, both maintained at 180C to prevent condensation and ensure complete transfer of semi-volatile compounds such as carbonates.

This setup ensures:

- No sample loss due to condensation of low-vapour-pressure species

- Stable transmission of reactive gases like propylene carbonate and ethylene carbonate

- Compatibility with dynamic events in battery fire testing environments

- Full compliance with ISO 19702 for FTIR-based fire effluent analysis

Portable atmosFIR FTIR gas analyser with heated sample line, configured for fire effluent monitoring.

Measurement Results

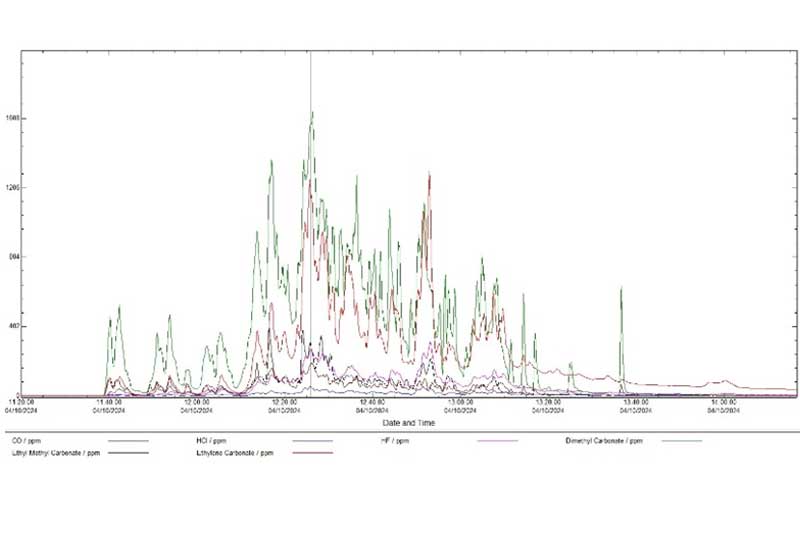

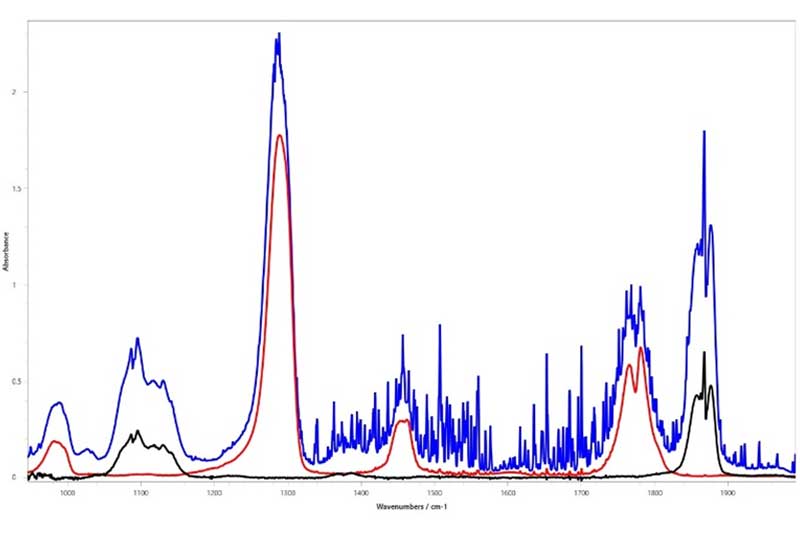

atmosFIR FTIR has been demonstrated in real battery fire test studies. Here are two examples of measurements of carbonates in a car battery fire. Effluent gases were extracted from a smoke density chamber into the analyser.

Complete Solution for Fire Gas Analysis

The atmosFIR FTIR analyser is compliant with ISO 19702 — the international standard for the analysis of toxic gases in fire effluents using FTIR spectrometry. This ensures confidence in both analytical accuracy and test method reliability, making it suitable for:

- Fire testing laboratories

- Battery fire testing and certification

- Regulatory compliance and materials research

In addition to carbonate measurement, the system supports simultaneous quantification of:

- HF, HCl, CO, CO2, NOx, NH3, and more

This provides a comprehensive gas-phase profile for researchers and safety engineers working with battery thermal runaway events.