Manufacturing

Manufacturing industries have a requirement to monitor and maintain emissions levels, both to the atmosphere for regulatory reasons and also ambient levels of gases within the factory. Often the requirements of monitoring for these industries are not as straight forward as incineration or combustion emissions. Gases can be "exotic" or specific to particular processes – such as HCN levels from carbon fibre manufacture – or gases can be higher concentration than is seen in typical combustion emissions – such as HF in brickworks.

For these industries, the customisable and well-support monitoring solutions from Protea Limited can ensure that the plant operators can keep on top of their emissions.

Carbon Fibre Manufacture

Carbon fibre is a unique material and is found in many high-tech industries such as sports car manufacture, wind turbine blade construction and sports equipment. The production of carbon fibre from acrylic fibre involves the baking of the fibre in ovens, which gives emissions of gas species including Hydrogen Cyanide (HCN). Protea’s range of gas analysers can provide a solution for the periodic or continuous measurement of gases from carbon fibre production in order to give reportable emissions values as required by legislation.

Paper & Pulp Industries

The P2000 emissions analyser is ideally suited to the harsh environments associated with Paper & Pulp Plants. The in-situ, multi-component Continuous Emission Monitoring (CEM) system has an integrated auto-zero and calibration facility, thereby removing the need for intervention by maintenance staff under normal conditions.

The instrument is compliant with international standards, meeting the stringent requirements of Environment Agencies. Certified under the MCERTS monitor certification scheme and therefore suitable for use in Europe, P2000 is also compliant with US EPA 40 cfr part 60 and 75.

Protea supply integrated CEM systems enabling plant-wide monitoring and reporting of gaseous emissions. The P2000 analyser, with associated Protea controller is capable of receiving inputs from other devices such as Oxygen, Dust and Flow analysers to complete the full emission measurement requirements in an integrated system.

Outputs from the system can be analogue or serial (MODBUS) depending on the site standard. Several P2000 analysers can be supported which also includes a data logging and reporting capability.

Paint Booth VOC Emissions

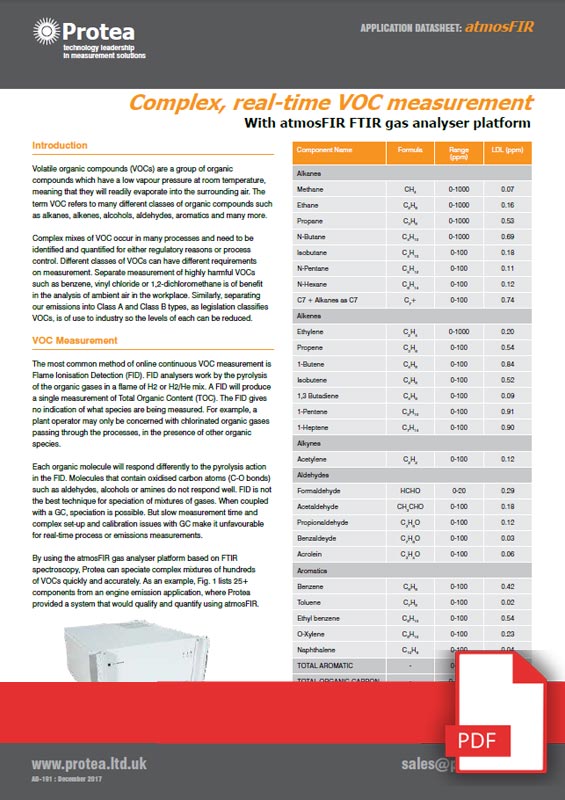

Paint booths can be major source of VOC emissions and paint shop operators in industries such as automotive manufacturing are required to monitor and control the emissions of VOCs. The control of emissions often includes the installation of a VOC abatement system, such as adsorbers, thermal or catalytic oxidisers, for reducing the solvent emissions. Understanding the requirements of the abatement system to use and validating its effectiveness requires a continuous an accurate of multiple VOC species.

Glass Wool Installation Manufacture

The installation of suitable installation material in buildings is a cost effective way to reduce energy costs. The manufacture of insulation from minerals or mineral products, such as glass. Recycling glass to form insulation materials is another way to keep the process "green".

The manufacturing of glass wool begins with glass melting and refining. Here, molten glass is produced in a furnace running up to 1700°C. The molten glass is formed into fibres through the rotary spin processes, with a chemical binder is simultaneously sprayed on the fibres as they are created, which is a resin to hold the fibres together in the finished product. Typically the binder consists of a solution of phenol-formaldehyde resin, water, urea, lignin, silane, and ammonia.

Emissions from the glass wool process need to be measured at various locations. The furnace flue gas for melting the glass as a starter will require monitoring for combustion gases such as CO, NOx and SO2, if fossil fuels are used.

In the forming and curing of the glass wool, emissions of components of the binder that have vaporized need to be monitored – so Formaldehyde, Ammonia, Phenol and other phenolic species all need to be measured. Protea’s range of FTIR gas analysers are ideal for measuring these gases, as we can detect and speciation out these gases. The multiple range of our equipment means that the high concentrations in process can be monitored. As well as the post-abatement emissions to atmosphere for legislative reporting can be measured with the same analyser, if the site is using wet ESP, thermal oxidiser, scrubbers or other filtration means.