Chemical & Pharmaceutical

The power of Protea's FTIR gas analyser technology is no more demonstrated than in industries where complex mixtures of multiple gases are seen and the operator needs to qualify and quantify the gas species; either for regulatory emissions monitoring requirements or for process studies and improvements, where cost savings and emissions reductions can be achieved by maximising understanding from monitoring.

VOC Emissions Analyser

Protea has used our VOC gas analysers in many projects requiring the monitoring of complex mixes of VOCs. In the chemical and pharmaceutical industry, VOC abatement plants such as scrubbers and carbon-bed systems are typical installations where the use of Protea analysers and our VOC analysis expertise have proved valuable to plant operators. They prove a very powerful and flexible tool in both process gas measurements and VOC emissions monitoring. In the laboratory, Protea can deliver instruments with all the chemometric software and support to enable users to measure hundreds of gases.

Protea can deliver products for use either as portable VOC analysers or fixed VOC emissions monitoring systems, giving plant operators or emissions testers the powerful capabilities of FTIR is easy to deploy packages. For the trained FTIR user in the lab or the field, full spectrum libraries and model building software allow analysers to be configure and re-configured again and again to measure an almost infinite range of gas applications.

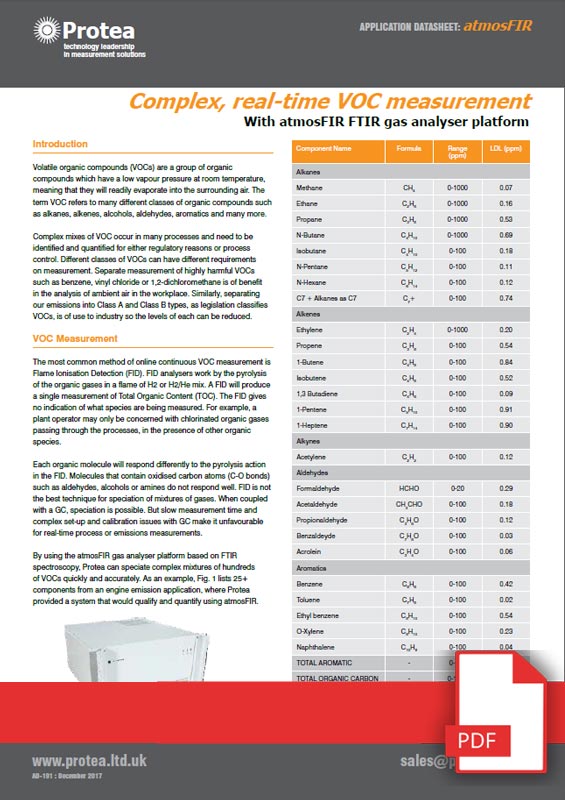

VOC monitoring of the following gases can be made easily made with our FTIR gas analysers, but there is almost no limit to the number of VOCs that Protea’s gas analyser can measure

Acrylate Monitoring

A customer had a requirement for continuous Ethyl Acrylate monitoring. The process operations emit multiple Acrylate species, all at low concentrations, but only Ethyl Acrylate being reportable to the EA under the terms of the IPC permit. A 204M FTIR analyser was deployed and a chemometric model was built specifically to target Acrylates, with the purpose of separating and accurately quantify the target Ethyl Acrylate species.

This technique shows the plant to be operating within compliance limits throughout batch manufacturing duration, with the continuous measurement from the FTIR analyser being of extreme benefit.

CFC Emissions Monitoring

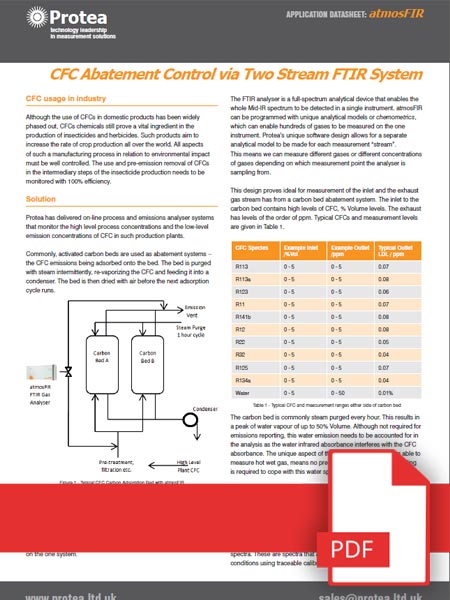

CFCs are used in the manufacture of insecticides and herbicides and the environmental impact of their use must be well controlled. The treatment of CFC emissions to reduce the emissions in the intermediary steps of production needs to be monitored with 100% efficiency. Protea’s portable CFC analysers and continuous CFC monitoring systems can be configured with various sample inlets and analytical modelling to enable multi-samples to be measured on the one system. This means that both inlet and outlet to abatement systems can be monitored using the one analyser.

Protea has delivered on-line process and emissions analyser systems that monitor both the high level process concentrations and the low level emission concentrations of CFC in such production plants. Commonly, activated carbon beds are used as abatement systems – the CFC emissions being adsorbed onto the bed. The efficiency of any abatement system is critical to its operation, not just in ensuring emissions are reduced as much as possible, but an efficient bed has cost savings for the operator.

The FTIR analyser is a full-spectrum analytical device that enables the whole Mid-IR spectrum to be detected in a single instrument. The system can be programmed with unique analytical models, which can enable hundreds of gases to be measured on the one instrument. This allows for a wide range of CFC emissions to be monitored, both a large number of different CFC species and also a large CFC concentration range. The following list is a few of the commons CFC emissions we have monitored.