PAS-Pro

When it comes to running continuous analysis system on process, a dedicated 24/7 running software environment is required. For this, Protea has developed PAS-Pro. PAS-Pro is built upon the same trusted components that make up the standard PAS application for the laboratory. However, the interface is stripped down to a more engineer-friendly interface. There is no need to change complex FTIR settings in the field. There is no need for the site engineer to worry about the chemometrics or the spectra.

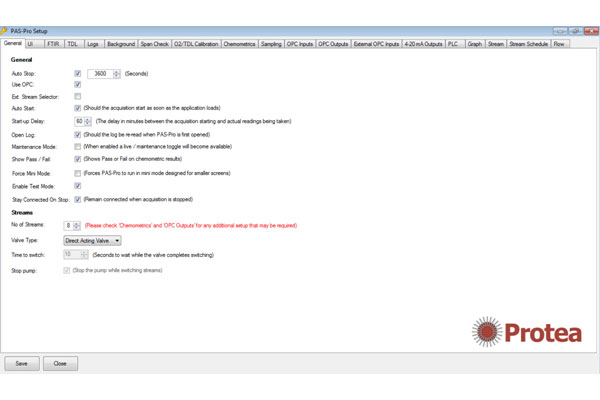

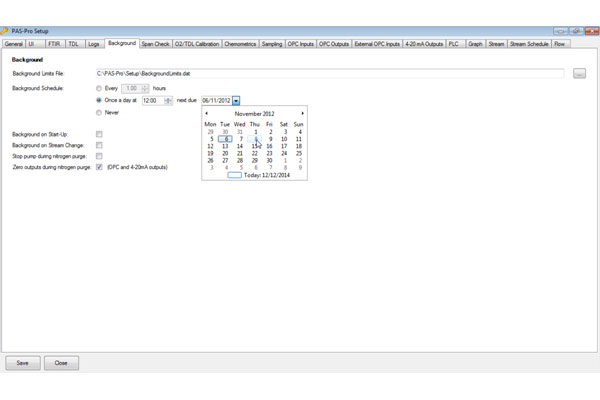

An .xml configuration file is built using the dedicated PAS-Pro Set-up application. In this file, we import the necessary configuration files to run the system: .config for FTIR set-up, .calib for chemometrics, sampling system .xml file. These files can all be built and supported by an applications specialist back at Protea. The files can be uploaded to the system remotely via a wireless data connection.

The operation of the system can easily be configured with background times, span check intervals, sample stream selection, reported results, data inputs and outputs etc. The configuration is via an easy to follow tabbed window, with no programming required.

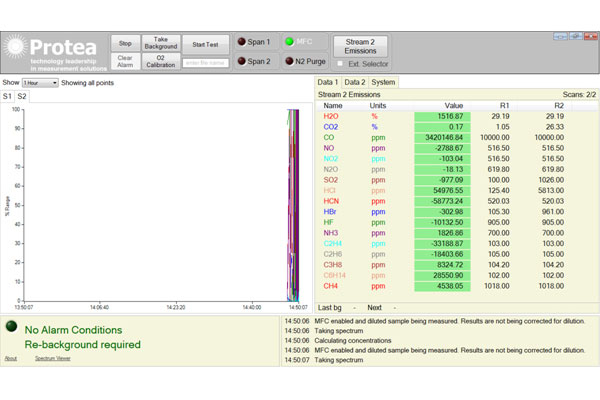

All the spectra are saved for a pre-determined time interval (usually 2 months), analysed in real-time and the data is outputted via 4-20mA, OPC or ModbusTCP protocols. The user interface is made up of a single window, often on a dedicated panel PC built into the system. Here via touch-screen the engineer can enable stream switching, zero purge, span check or background the system.

Concentration readings are displayed for the last measurement, together with a result quality indicator. The alarm window indicates if there are any faults with the system and the event log updates with each task the system has carried out.

More functionality can be added to the Spectrum Viewer. Just ask what you want to do with your spectra and we can supply a solution!

Data Handling and Reporting

Commonly for laboratory and mobile emissions testing, a single outputted data file of data/time and analytical results is required and PAS-Pro writes all data locally to a .csv file (one file per day).

On process and continuous emissions measuring systems, output of "real" data needs to be instantaneously transmitted to the plant. This can either be for recording in the plant data historian or for a response to be made in the operation of the process. In these cases, system with PAS-Pro have been designed with industry standard data sharing protocols built-in.

OPC

OPC (or Object Linking and Embedding (OLE) for Process Control) is an inter-manufacturer data sharing protocol, which allows various components of an automation system to send and receive data in real-time. OPC works on the principal of an OPC Server offering data and a remote OPC Client who accesses that data. Protea's analyser systems offer both OPC Server and OPC Client operation.

The measurement data (concentrations, temperature, flow, pressure) is offered on an OPC DA v2.05 compliant server. Global and local alarms for the system are also available. System operation (start/stop, purge, zero, span) can also be controlled via dedicated OPC tags on the server. The OPC Client features allow remote OPC Servers over a network to be browsed and data tags added into the system. This allows real-time process data to be recorded alongside the information from the analyser system.

Modbus

Protea also utilised Modbus as a data transfer protocol, and we can offer ModbusTCP and Modbus RTU serial as standard. Gas analyser concentration readings as well as analyser health and alarm settings can be read via the Modbus connection.

Analogue

Legacy data I/O via digital and analogue (4-20mA) signals are built into the analyser hardware, with no need for extra data cards on the PC.